Mooring Tethers

TfI Marine Components combine the qualities of rubber with the strength of thermoplastic, to deliver a tailored stress strain response for a wide range of applications.

With the support of the Marinet programme and SEAI, TfI successfully tested its mooring tethers on a wave energy converter in the wave tank at ECN Nantes in November. The tests evaluated performance through a wide range of sea states and robustly tested the tethers protective ability across a range of storm conditions. The week's test concluded with an evaluation during the equivalent of a 3 hour 100 year storm.

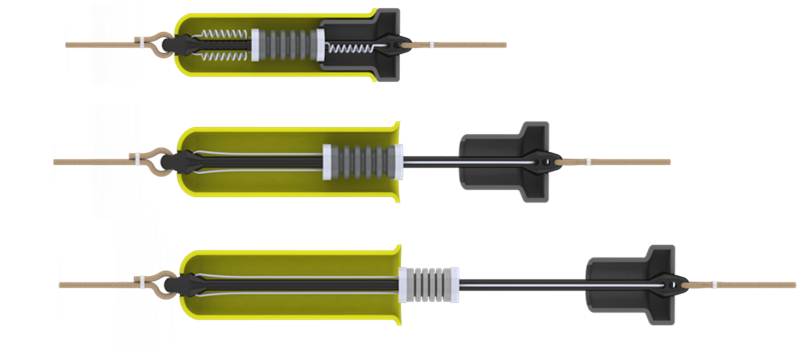

Sample Imagery

Top to Bottom :- Unloaded, Normal Loads, Max Loads

TfI's Mooring Tethers significantly Reduce

- Mooring Forces,

- Mooring System Costs,

- Footprints/Watch Circles and

- Noise Emissions

and can be used on a wide number of marine installations.

- Navigation & Research Buoys,

- Aquaculture,

- Marine Energy

- Oil & Gas Installations

TfI's Corrugated Springs for use in Motion and Force Control can be used as an alternative to Gas Springs or End Stops. These passive polymer components offer lower Capex and Opex alternatives to current active response systems.